LEO ELECTRONICS (VIETNAM) Ltd

LEO ELECTRONICS is a manufacturing company operating with a dual-base system in Japan and Vietnam, providing integrated services in press processing, sheet metal fabrication, and assembly. Leveraging precision processing technologies and strict quality management developed in Japan, our Vietnam base achieves cost competitiveness and flexible production capabilities.

Our business is divided into three main areas:

1. Metal turret punch press:

Precision parts for financial equipment, medical devices, motorcycles and automobiles, office equipment, security devices, and leaf springs

2. Sheet metal processing:

High-precision components for medical equipment, Wi-Fi and radio devices, and ATM transmitter parts

3. Assembly:

Complete assembly of products such as coin sorters, barcode printers, blood purification devices, and security equipment

By integrating these capabilities, we respond to a wide range of needs from small-lot production to mass manufacturing. Our products are trusted and adopted across various industries, including electronics, industrial machinery, and precision devices, both domestically and internationally.

Basic info

Socialist Republic of Vietnam Hai Phong Mao Dien Phuc Dien Industrial Zone

0220-354-5987

0 $

Private

370

https://www.nc-net.or.jp/company/95657/

http://www.leotokyo.co.jp/index_j.html

Web meeting / Venue

Japanese / English / Vietnamese

Vietnam Booth Exhibit / Online Exhibit

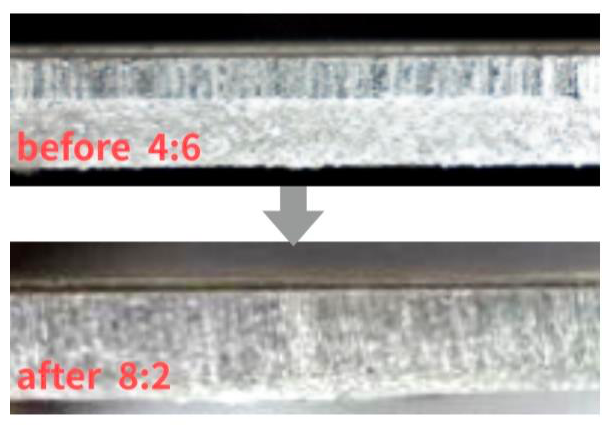

High-efficiency metal sheet processing with punch & laser combination machine

N/A

Pressed Parts

Sheet Metal Parts

Assembly

Private