EXT Engineer Co., Ltd.

Since our founding in 1977, we have continued to deliver precision machined parts to customers all around the country. To satisfy our customers' ever-changing demands, we are expanding as a precision machined parts specialty factory by nurturing competent experts and upgrading the factory production environment. We have three production bases: the head office factory in Tamura City, Fukushima, the West Japan Sales Office and Shizuoka Factory in Fujieda City, Shizuoka as sales and production base in the West Japan region, and Vietnam factory (EXT ENGINEER VIET NAM CO., LTD) in northern Vietnam.

All three factories specialize in machining and have a total of more than 250 machines, which is an astonishing quantity. We build an in-house integrated production system that manages everything from material procurement to processing, surface treatment, and simple assembly.

Business contents (achievements)

FA parts, semiconductor-related parts, automotive parts or related parts, construction heavy equipment parts or related parts, power generation/power related parts, aircraft related parts, medical related parts, optical related parts, other cutting parts.

●Same-day quotation support.

In order to meet our customers demand in recent years, we have created data on material costs and costs that have been processed that allow to provide quotation within 24 hours.

●We respond to low cost mass-produced machined parts.

For customers who need to keep costs down, we can produce at our factory in Vietnam to reduce costs as much as possible.

●We accept batch orders for wide-variety small-lot production.

We accept orders for entire lots of machined equipment and machined parts for automatic machines. For machined parts used in machine equipment parts, we accept batch orders for all machined parts from the smallest parts to large parts, including round parts, square parts, hardening welding, and polishing plating. Discounts are available for batch orders. We respond to short delivery times by utilizing the mobility of equipment and the mobility of shift production.

●We will inquire about your budget and pricing before making a proposal.

Please let us know in advance if you have a budget or pricing for parts or processed goods, and we will provide a cheaper processing technique for processed parts with a strict price.

●Compatible materials

Materials currently processed in-house are S45C, SS400, stainless steel, 304, 303, 316, 316L, 630, 310.

Aluminum, 5056, 5052, 6063, 6061, 2017, 2011, 7075, special steel, SK3, SK4, SKD11, SKD61, SCM415, 435, SNCM220H, SUJ2, NAk55, NAK80, titanium, Hastelloy, brass, copper, gunmetal, resin, etc.

●Quality assurance system

Our quality assurance department employs the most up-to-date inspection equipment, 3D, contour measurement, image measurement, roughness measurement, microscope, projector, etc. We inspect in accordance with ISO9001 and provide inspection report.

★August 2013, the Vietnamese government issued an investment license to our Vietnam factory.

★July 2014, the Vietnam factory started the operation with around 40 machine tools.

★August 2014, we started Taiwan Taipei Liaison Office <<Taiwan Steel Materials, Materials, Machine Tools Procurement Counter>>

★August 2018, the second factory in Vietnam was completed

★December 2018, The Minister of Economy, Trade, and Industry recognized us as a regional future driving company

★September 2019, we signed a commercial collaboration with Wakoh Engineering Co., Ltd., a sheet metal welding can manufacturing and switchboard design and manufacturing company based in Hitachi-shi, Ibaraki

Basic info

Japan Fukushima Aza Nanoka Ichiba, Tokiwa, Tokiwa-machi, Tamura 66

0247-77-4196

1,300,000,000JPY

10,000,000JPY

120

https://www.nc-net.or.jp/company/72379/

http://www.extengineer.co.jp/english/index.html

Venue

Japanese / English / Chinese / Vietnamese

Vietnam Booth Exhibit / Online Exhibit

Simultaneous 5-axis machining center processing: prototype for difficult-to-cut materials

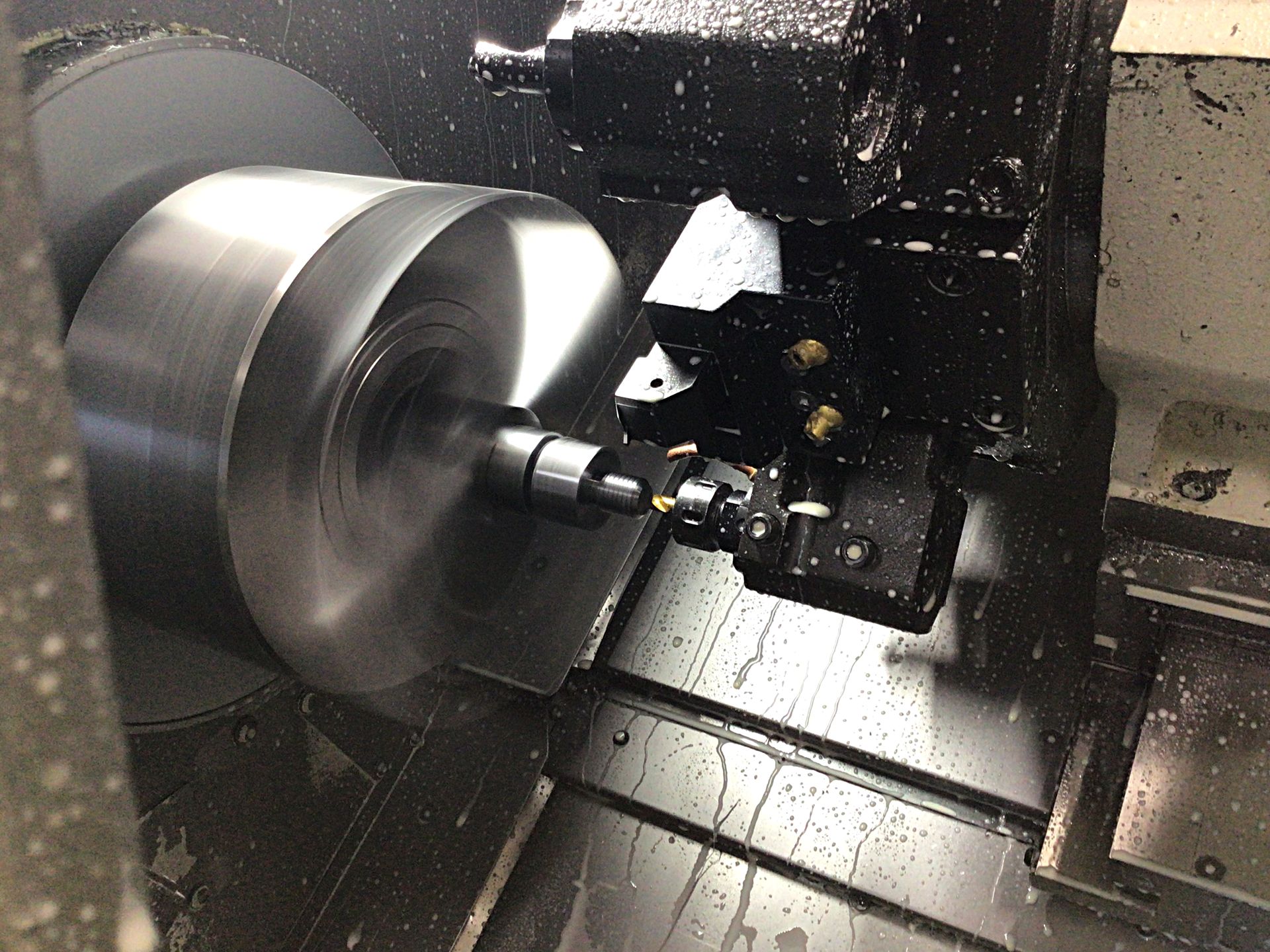

CNC automatic lathe

NC combined lathe processing

5 axis

Private