BUNRI Inc.

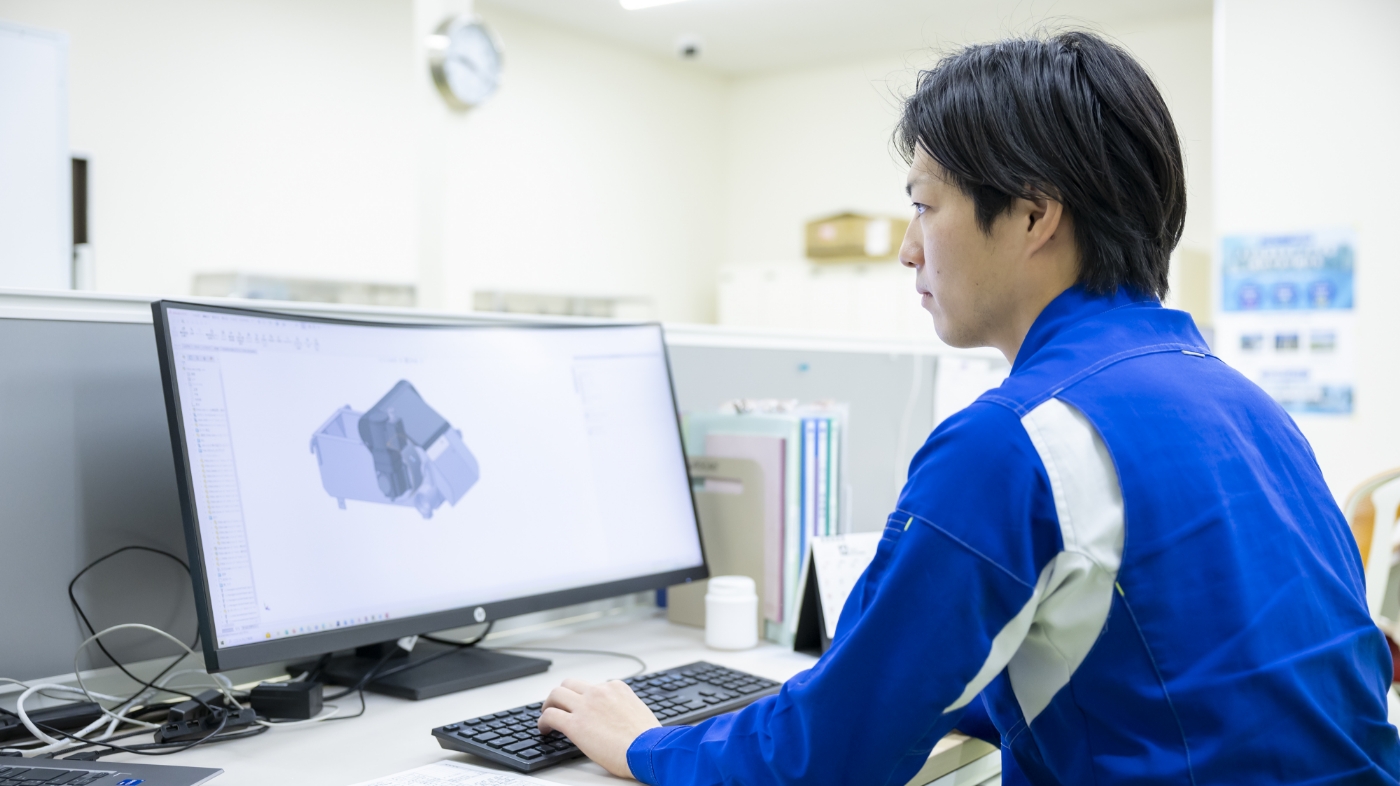

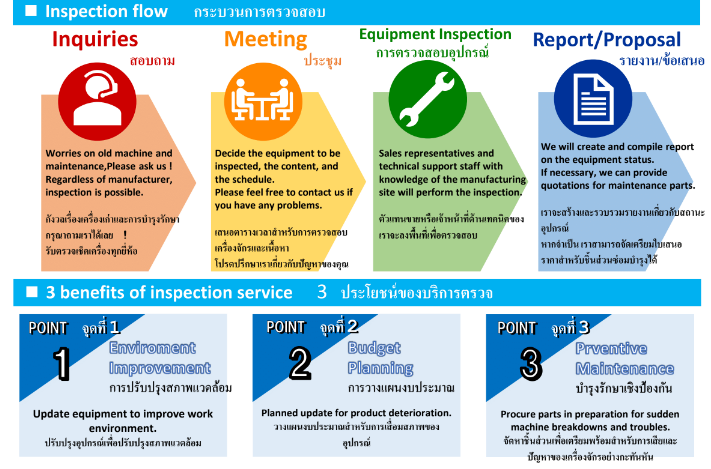

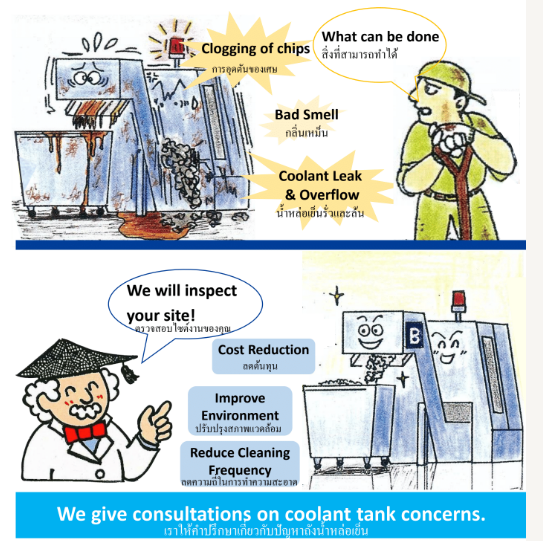

BUNRI is a specialized manufacturer that develops, manufactures, sells, and provides after-sales services for coolant filtration and chip treatment systems, which are equipment that filter coolant mixed with chips generated in the product manufacturing process.

Basic info

Kingdom of Thailand Bangkok Lumpini , Phatumwan 87/1 Suite 1109 11th Floor Capital Tower, All Seasons Place , Wireless Road

02-080-6128

Private

60,000,000JPY

5

https://www.nc-net.or.jp/company/103490/

https://www.bunri.com/

Web meeting

Japanese / English / Thai

Online Exhibit

coolant filtration

chip treatment systems

AISIN CORPORATION

JATCO Ltd

DENSO CORPORATION.

Nissan

MITSUBISHI HEAVY INDUSTRIES, LTD